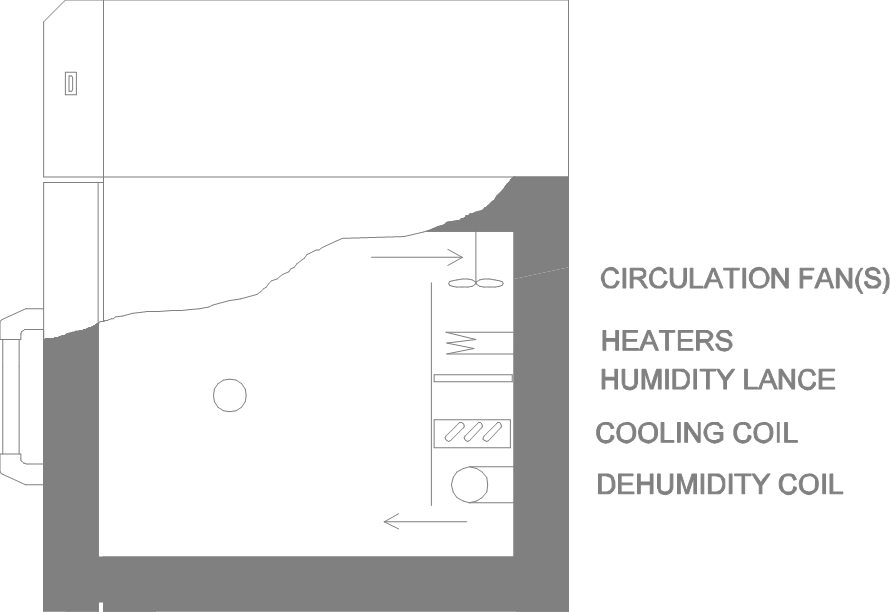

Inside an Environmental test chamber

April 15, 2021

An environmental test chamber, often referred to as a climatic chamber, is an enclosure used to test the effects of specific environmental conditions. These tests are carried out on industrial products, materials, electronic devices, biological items and many other components.

The chambers operate by controlling the parameters of temperature and humidity, with a good airflow being an important part in achieving even distribution and uniformity.

Temperature Control

To achieve a set level of temperature the chamber must be able to both heat and cool to achieve and control at the desired level.

Heating

– this is done using electrical heating elements sized accordingly to the chamber specification and positioned in the airflow to give even distribution and uniformity.

Cooling

– this is done using a mechanical cooling system with close loop control. The main parts of a single stage cooling system are compressor, condenser, expansion valve, solenoid valves and cooling coil (Evaporator). Evaporators are sized to achieve a specific cooling duty and are generally located in a conditioning plenum to give even distribution into the test area. A single stage system will achieve temperatures down to -40°C.

A cascade system is a two stage cooling system and has the addition of a second compressor. The system uses two refrigerants, one type for the first stage and another for the second stage. A cascade system will achieve temperatures down to -65°C.

Humidity Control

To achieve a set level of humidity the chamber must be able to both humidify and dehumidify in order to achieve and control at the desired level.

Humidity

– this is done by introducing steam into the test area, the steam is generated outside the test area and is pulsed into the conditioning plenum in a controlled manner.

Dehumidity

– this is done by creating a controlled cold surface using the main refrigeration cooling system, moisture from the turbulent airflow is then condensed on to this cold surface.

All test chamber utilise these basic components and it is the expertise at JTS that pulls together the right combinations to ensure that the chambers we supply meet the customer specification.

Please get in contact to discuss your test chamber requirements, if one of our standard machines doesn’t meet the test specification we will be able to size a bespoke build that definitely will.

We’re excited to welcome Alan Phillips to our service team. Alan joined us this summer and has already been making a big impact, helping customers get the very best out of their test chambers. 👏 At JTS, we know that regular servicing is the key to keeping your equipment reliable, accurate, and compliant. That’s why we offer a comprehensive Service Package designed to: ✅ Extend equipment lifespan ✅ Prevent costly breakdowns ✅ Maintain testing accuracy & compliance Our expert technicians provide: 🔧 Full functional checks 📏 Calibration & performance verification ⚙️ Replacement of worn parts 📝 Detailed service reports With JTS, you get fast, efficient service from specialists who know your chambers inside out — so you can keep operations running smoothly with minimal downtime. 📅 Ready to book your service? Drop us a message or get in touch today for your quotation andrea@jts-test-chambers.co.uk

James Technical Services Limited having been involved in electric car, battery development and testing over the past 7 years have now installed two 11kW charging points at the factory in Talgarth mid Wales. These points can be used by customers and employees 😊 JTS have always been following the progress of the battery development and have purchased their first electric vehicle which will be used by the employees to carry out sales / site visits. The container test chamber below is used by various car manufacturers for electric vehicle battery testing. This is just one example of a battery testing facility JTS can supply.